About Us

Clean Energy Recyclers (CER) provides end-of-life recycling solutions for wind turbine blades, helping clean energy stay clean. By transforming decommissioned blades into valuable composite materials for industrial and commercial use, we reduce landfill waste and support a truly circular economy.

Driven by innovation, responsibility, and sustainability, we’re building a future where clean energy doesn’t come with a waste problem.

Zero Waste

CER’s ultimate aim is for 100% recovery and upcycling rate. Not only is waste unsustainable, it is a lost revenue opportunity.

Responsible

As stewards of sustainable practices, we hold ourselves accountable for our actions and accept the consequences.

Innovative

Creating treasure from trash requires creativity and unwavering belief in a solution.

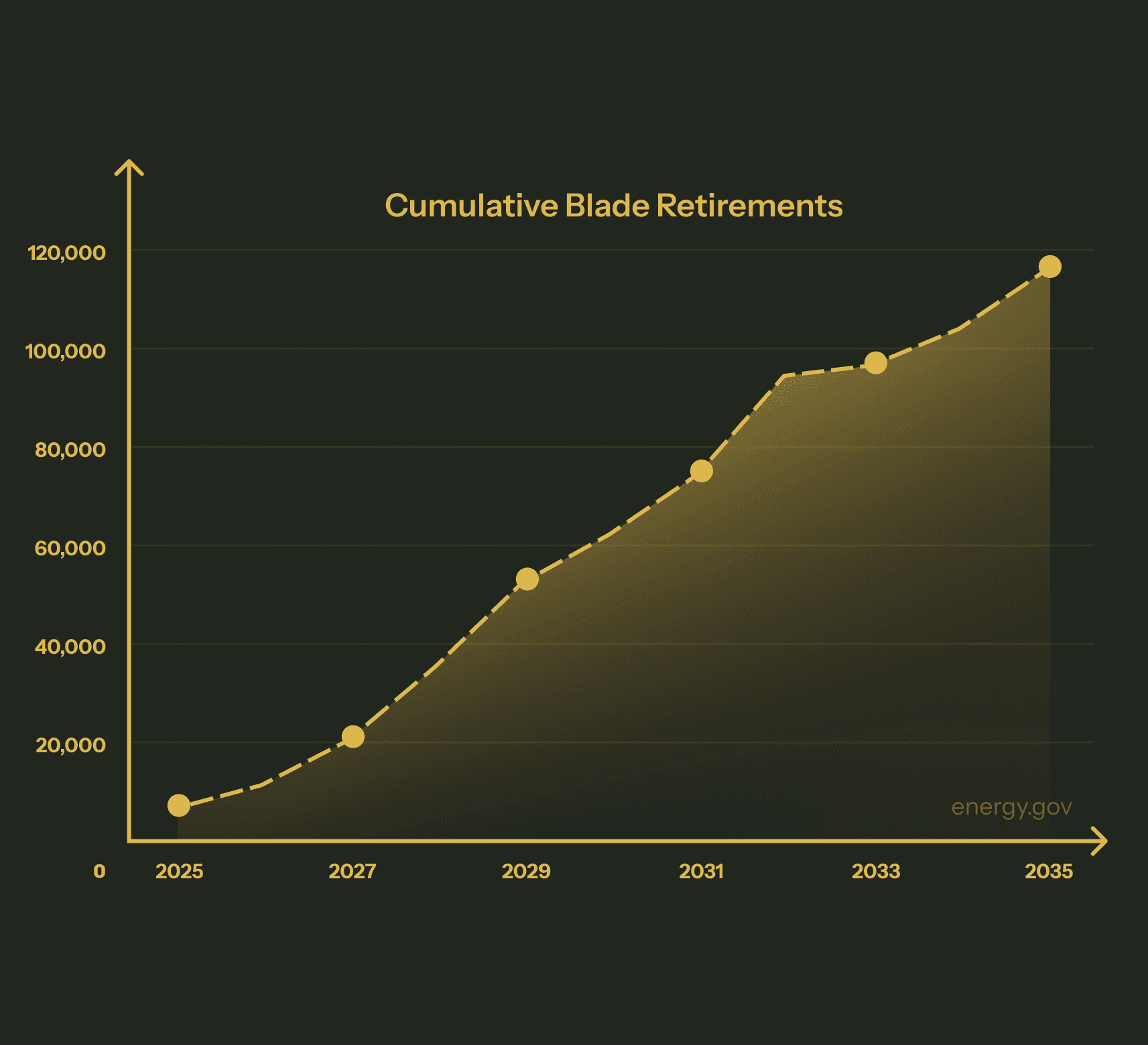

Each year, thousands of fiberglass composite blades reach end of life. With landfill bans tightening and a surge in blade retirements expected in the next decade, the U.S. urgently needs scalable recycling solutions. Leading utilities and advanced manufacturers like Avangrid, GE Vernova, EDP, Ørsted, and Vestas have pledged to recycle 100% of their blades. CER is here to meet that demand.

“We plan to recycle 100% of wind turbine blades decommissioned across our wind farms by 2030 (with a near-term goal to recycle 50% of all blades decommissioned by 2025).”

– Avangrid 2023 Sustainability Report; Owner of 4,000 wind turbines (7.5GW Capacity) in the U.S.

Services

CER aims to partner with turbine owners, OEMs, and contractors to provide blade recycling services. We will accept blades of any size delivered to our facility and mechanically process them into millimeter size composite material. We will provide:

Certificates of

destruction and recycling

ESG traceability data

Project specific environmental

impact reports

Material Sales

Our processed materials—fiberglass strands, epoxy, and balsa wood—serve a wide range of applications. We offer custom blends and sizing, with lab tested specifications to meet industrial needs at lower costs than existing supplies and with a reduced carbon footprint.

Concrete Aggregate

Substitute for traditional aggregates at ready mix plants

Concrete Reinforcement

Chopped fiberglass strands enhance tensile strength and binding properties of concrete

Insulation

Substitute for glass cullet or fibrous material

Waste-to-Energy

High calorific value for recovery processes

Oil & Gas

Functional as lost circular material (LCM) in fracking processes

Plastic Lumber & Particle Board

Recycled, predictable feedstock

Contact Us

We welcome the chance to partner with decommissioning contractors and offtakers to discuss how our recycled blade materials can meet your sustainability goals, with full documentation, quality controls, and traceability aligned with industry demands.

info@cleanenergyrecyclers.com

@2026 Clean Energy Recyclers